The Perfect Build!

The major difference between an individually crafted Luthier built instrument and a factory made instrument are that the Luthier can adjust every small nuance during the build depending on the wood type and literally how each individual piece of wood responds !

The perfect instrument must be crafted to sound great,look great and be structurally sound.

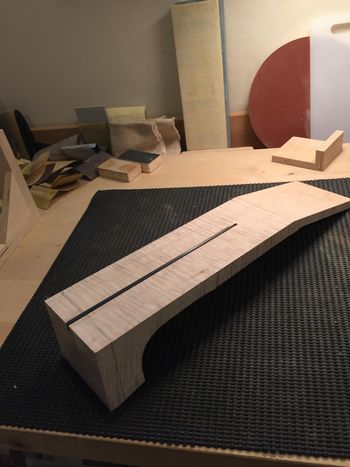

This requires careful wood selection of stable well aged materials that have been dried to less than 10% moisture content.

During the building process we monitor and control the humidity of the workshop to be in the 45-50% humidity range.All tonewoods are acclimatized and stabilized to the workshop conditions before the building process begins.

We are very lucky to have some of the highest grade most sought after tonewoods right in our own backyard! These woods are shipped around the world to many of the top instrument makers and include figured Maple,Sitka Spruce and Western Red Cedar !

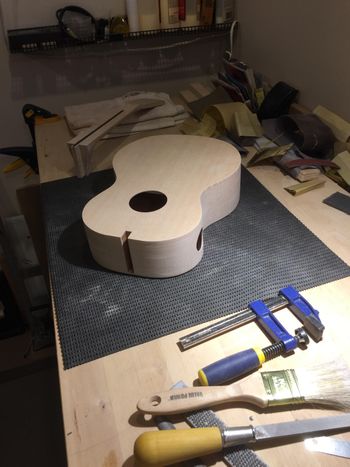

Sides In Mold Ready For Top and Back !